The demand for special effects in product packaging is increasing, seeking sensory experiences of the consumer when handling the product in a sales shelf, or during its consumption. Adhesive labels are a fundamental support to incorporate varnishes that provide a different touch.

Wine bottles, cosmetic packaging, cream jars and any product that seeks to capture our attention with effects are applications, which their use is increasingly necessary.

Although screen printing is still the ideal printing system to reproduce them since it is the one that contributes the most volume of ink and allows a very good regulation of the deposit in the label finishing lines, flexography with ultraviolet curing inks is the printing system that is evolving the most in this type of finish.

This is due to the innovation in special effect varnishes and especially to the new types of engraving of the anilox cylinders, which allow an increase in the contribution of ink to the substrate to ensure the tactile effect.

Our advice in this type of decision is to increase the theoretical volume of the anilox in a relevant way, but with a type of engraving (cell drawing) that ensures a homogeneous extension.

Depending on the type of coating and the composition of solid particles, it may be necessary to carry out tests to ensure the correct curing at high speed.

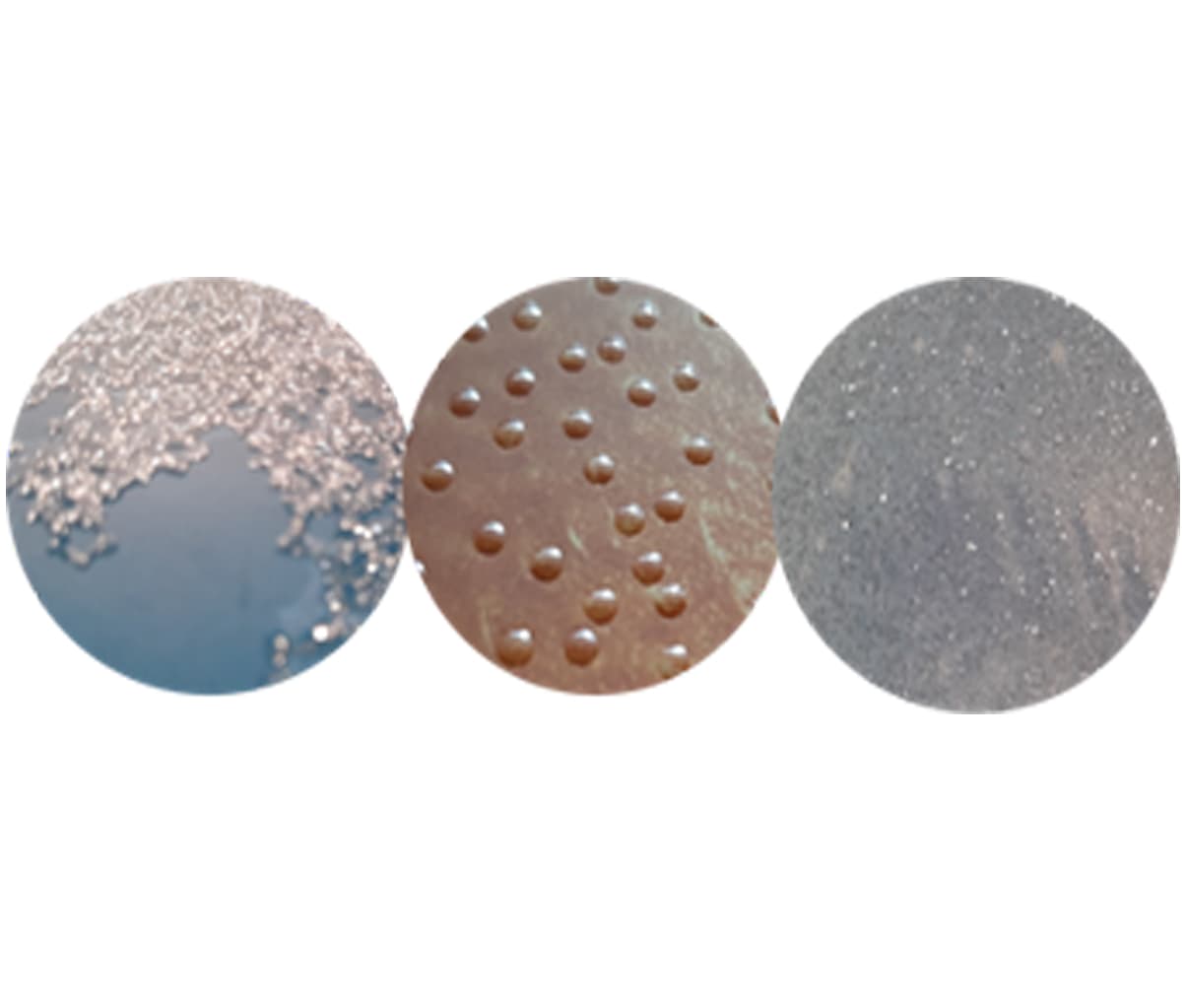

Ibeslab TACT is a type of laser engraving specially developed to achieve visual and tactile effects such as 3D, relief, rough, sand, etc.

The Ibeslab TACT Recording has a stepped volume range that reaches up to 80 cm3 / m2. It has been designed so that the open cell of the anilox transfers as much as possible to the plate and can form the necessary layer on the substrate to achieve the desired finish.

With this type of anilox, varnishes and special coatings have the perfect vehicle to enhance performance, allowing a constant and controlled ink deposit to be printed. A good choice of the other flexo variables such as the type of foam or photopolymer can help to optimize the result.

FEATURES AND BENEFITS

- Open cell recording for increased input.

- Adjustable volume and lines to optimize the finish

- Easy cleaning of the anilox

- Constant and controlled ink deposition.

- Compatible with any photopolymer plate

- Ideal for UV curing varnishes and lacquers

To learn more about our range of recordings for anilox visit our page: https://www.ibeslab.com/en/anilox/